Navigating Injection Molding Vendors in China

The important meeting has recently finished, your new product has been approved, the schedule is tight, and funding is, to put it mildly, limited. Then a voice—perhaps your manager or the CFO—drops the line that gives every project manager a shock: “We should look at sourcing this from China.”

Of course, you acknowledge. It seems sensible at first glance. The potential savings can be massive. But your mind is already racing. You’ve heard all the horror stories, right? The nightmare of defective parts, opaque communication, and delayed, off-spec shipments. It can feel like you’re being asked to walk a tightrope between landing a huge cost win for the company and steering your project straight into a ditch.

Here’s the thing, though. Sourcing plastic mold can be a calculated project. It’s simply another project with clear steps. And like any project, it succeeds or fails based on the process you follow. It’s not just about the lowest bid but selecting the best partner and overseeing every step. Disregard those scary tales. Here’s a practical playbook to nail it.

Initial Step: Prepare Your Information

Before you mention “supplier” or browse Alibaba, organize your internal data. In fact, most overseas manufacturing headaches stem from a vague or incomplete RFQ. You cannot expect overseas partners to interpret your unspoken requirements. Sending a vague request is like asking a builder to quote you for “a house.” The replies will range from absurdly low to exorbitant, none of which help.

Your goal is to create a Request for Quotation, or RFQ, package that is so clear, so detailed, that it’s nearly impossible to misinterpret. It’s the cornerstone of your entire effort.

What belongs in your RFQ?

Start with your 3D design files. These are non-negotiable. Stick to universal formats like STEP or IGS to avoid any compatibility headaches. This is the master blueprint for your part’s geometry.

Yet 3D models don’t cover everything. You also need detailed 2D drawings. This is where you call out the stuff that a 3D model can’t communicate. I’m talking about critical tolerances (like ‘25.00±0.05 mm’), material specifications, required surface finishes, and notes on which features are absolutely critical to function. If a specific surface needs to be perfectly smooth for a seal, or a particular hole diameter is vital for an assembly, your 2D drawing needs to shout it from the rooftops.

Then specify the material. Don’t label it simply “Plastic.” Even “ABS” alone is too vague. Be explicit. Specify SABIC Cycolac MG38 in black, if that’s the resin you need. Why so detailed? Because there are thousands of plastic variations. Naming the precise grade locks in the mechanical, thermal, and aesthetic properties you need with what is plastic mold.

They can offer alternatives, but you must provide the initial spec.

Finally, include the business details. What’s your forecasted annual volume (EAU)? You must specify if it’s a 1K-part tool or a 1M-part production run. The tool design, the number of cavities, and the price per part all hinge on this number.

The Great Supplier Hunt

With your RFQ perfected, now, who do you send it to? The internet has made the world smaller, but it’s also made it a lot noisier. It’s easy to find a supplier; it’s hard to find a good one.

You’ll probably kick off on Alibaba or Made-in-China. These are great for casting a wide net and getting a feel for the landscape. But think of them as a starting point, not the finish line. Narrow your pool to about a dozen promising firms.

But don’t stop there. Consider using a sourcing agent. They do cost extra. Yet top agents deliver reliable, audited suppliers. They handle local liaison and oversight. For a first-time project, this can be an invaluable safety net. Consider it timeline insurance.

Another classic method? Trade shows. If you can attend, shows such as Chinaplas transform sourcing. In-person meetings trump emails. Inspect prototypes, interview engineers, and sense their capabilities. Also, leverage the tried-and-true referral network. Consult trusted colleagues. Peer endorsements carry huge weight.

Shortlisting Serious Suppliers

With your RFQ dispatched to dozens of firms, bids begin to arrive. Some will be shockingly low, others surprisingly high. Now, sift through and shortlist 2–3 reliable candidates.

How do you do that? It’s a bit of an art and a science.

Step one: audit communication. Do they respond quickly and clearly? Can they handle detailed English exchanges? The true litmus: are they raising smart queries? Top vendors will critique and inquire. “Have you considered adding a draft angle here to improve ejection?” or “We see your tolerance requirement here; our CMM can verify that, but it will add to the inspection time. Is that acceptable?” That’s a huge positive sign. You know they know their stuff. Anyone who simply agrees to all specs is a red flag.

Next, dig into their technical capabilities. Request their machine list. Review examples of parts akin to your design. If you’re making a large, complex housing, you don’t want a shop that specializes in tiny gears.

Finally, inspect the factory. This is not optional. You would never hire a critical employee without an interview, so why would you send tens of thousands of dollars for a tool to a company you’ve never truly vetted? Either visit in person or engage a local audit service. They perform a one-day factory inspection. They will verify the company is real, check their quality certifications like ISO 9001, assess the condition of their machinery, and get a general feel for the operation. That small investment can save you thousands.

From Digital File to Physical Part

After picking your vendor, you’ll agree on terms, typically 50% upfront for tooling and 50% upon first-sample approval. Then comes the real action.

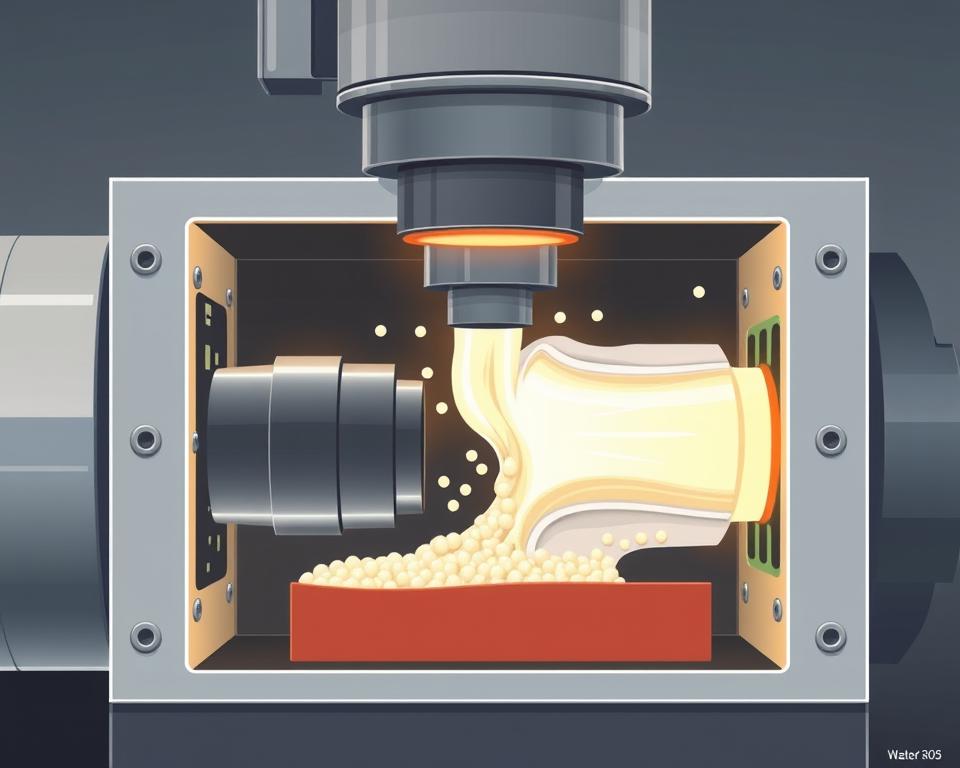

The first thing you should get back after sending your payment is a DFM report. DFM stands for Design for Manufacturability. It’s the engineering critique for moldability. The report calls out sink-risk zones, stress-causing corners, and draft angle gaps. Comprehensive DFM equals a top-tier supplier. It’s a collaboration. You work with their engineers to refine the design for optimal production.

With DFM sign-off, toolmaking begins. In a few weeks, you’ll see “T1 samples are on the way.” These are the very first parts off the new tool. It’s your test of success.

Expect T1s to need tweaks. This is normal! There will be tiny imperfections, a dimension that’s slightly out of spec, or a blemish on the surface. You critique, they refine, and T2 plastic mold company parts arrive. This process might take a couple of rounds. Build buffer time for sample iterations.

Eventually, you will receive a part that is perfect. It meets every dimension, the finish is flawless, and it functions exactly as intended. This is now the benchmark sample. You formally approve it, and this sample is now the standard against which all future mass-produced parts will be judged.

Crossing the Finish Line

Landing the golden sample is huge, yet the project continues. Now comes full-scale production. How do you maintain consistency for part 10,000?

Put a strong QC process in place. Typically, this means a pre-shipment audit. Use a third-party inspector again. For a few hundred dollars, they will go to the factory, randomly pull a statistically significant number of parts from your finished production run, and inspect them against your 2D drawing and the golden sample. They’ll send you a detailed report with photos and measurements. After your approval, you release the shipment and final funds. This step saves you from a container of rejects.

Lastly, plan logistics. Clarify your Incoterms. Are you on FOB terms, where they load and you take over? Or is it EXW (Ex Works), where you are responsible for picking it up from their factory door? Your Incoterm selection drives landed expenses.

Sourcing from China is a marathon, not a sprint. It’s about building a relationship with your supplier. View them as allies, not vendors. Open dialogue, trust, and rigorous procedure deliver results. No question, it’s demanding. But with this framework, it’s one you can absolutely nail, delivering the cost savings everyone wants without sacrificing your sanity—or the quality of your product. You’re set to succeed.